As someone who’s spent years working with synthetic and natural stone materials in interior design and construction, I’ve seen the rise of PU stone (polyurethane stone) as a versatile, lightweight alternative to traditional stone. Its realistic texture and affordability make it a favorite for homeowners and designers alike, but one question I often hear is: Can PU stone surfaces be polished? The short answer is yes, but it’s not as straightforward as polishing natural stone like marble or granite. Drawing from my experience with PU stone in various projects, I’ll explain whether and how you can polish it, the challenges involved, and practical tips to achieve a sleek, glossy finish—or maintain its natural look if that’s your goal.

Understanding PU Stone: What Makes It Different?

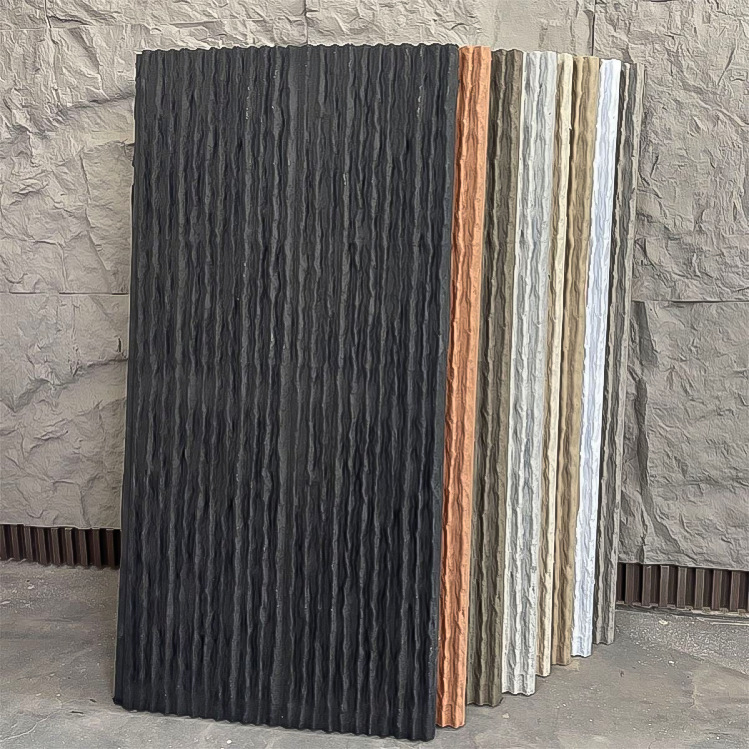

Before we dive into polishing, let’s clarify what PU stone is. PU stone is a synthetic material made from polyurethane resin, often mixed with fillers like stone powder to mimic the look and feel of natural stone. It’s commonly used for wall cladding, furniture accents, and decorative panels due to its lightweight nature, durability, and cost-effectiveness. Unlike natural stone, which is quarried and inherently dense, PU stone is a molded product with a surface that’s either pre-finished with a protective coating or left with a textured, matte appearance.

I first encountered PU stone when designing a feature wall for a client who wanted the aesthetic of slate without the hefty price tag or installation challenges. The result was stunning, but over time, the surface showed signs of wear—scratches and dullness—that led me to explore polishing as a solution. Here’s what I’ve learned about polishing PU stone and how to approach it.

Can PU Stone Be Polished? The Short Answer

Yes, PU stone surfaces can be polished in many cases, but the process and results depend on the type of PU stone, its surface finish, and the tools and techniques used. Unlike natural stone, which can be polished to a high gloss using diamond pads and heavy machinery, PU stone requires a gentler approach due to its synthetic composition. Over-polishing or using the wrong methods can damage the surface, strip its protective coating, or alter its intended texture.

Factors That Affect Polishing PU Stone

Whether you can successfully polish PU stone depends on several key factors. Here’s a breakdown of what I consider before attempting to polish a PU stone surface:

1. Surface Finish

PU stone comes in various finishes—matte, textured, or glossy—and each responds differently to polishing:

Matte or Textured Finishes: These are designed to mimic raw stone like travertine or limestone. Polishing can smooth out the texture, potentially ruining the natural look. I’ve seen clients try to polish textured PU stone, only to end up with an uneven, unnatural sheen.

Glossy or Coated Finishes: Some PU stone products have a factory-applied glossy coating. Polishing these is possible to restore shine, but you must avoid stripping the coating.

Uncoated PU Stone: Raw PU stone without a protective layer is more delicate and prone to damage during polishing.

My Tip: Always check the manufacturer’s specifications or contact the supplier to confirm the finish type before polishing.

2. Material Composition

PU stone varies in hardness and density depending on the polyurethane formula and fillers used. Some brands incorporate more stone powder, making the surface harder and more polishable, while others are softer and foam-like, which limits polishing potential. I once worked with a high-density PU stone panel that polished beautifully to a satin finish, but a softer version from another brand scratched easily when I tried the same technique.

My Tip: Test a small, inconspicuous area first to gauge how the material responds to polishing.

3. Protective Coating

Many PU stone products come with a UV-resistant or waterproof coating to enhance durability. Polishing can wear down this coating, exposing the underlying material to damage or discoloration. I learned this the hard way when I polished a coated PU stone wall too aggressively, causing the surface to lose its water-repellent properties.

My Tip: If the surface is coated, use a non-abrasive polish and avoid heavy sanding.

4. Intended Use

The location of the PU stone affects polishing decisions. For example, PU stone used for indoor wall cladding may not need a high-gloss finish, while a countertop or furniture piece might benefit from a polished look for aesthetic and maintenance reasons.

|

Factor |

Impact on Polishing |

Consideration |

Recommended Approach |

|---|---|---|---|

|

Surface Finish |

Matte/textured finishes may lose texture |

Check manufacturer specs |

Light polishing for glossy finishes |

|

Material Composition |

Softer PU stone scratches easily |

Test small area first |

Use low-grit abrasives for soft materials |

|

Protective Coating |

Polishing may strip coating |

Confirm coating type |

Use non-abrasive polish |

|

Intended Use |

Indoor vs. outdoor affects gloss needs |

Match polish to aesthetic |

Satin finish for indoor walls, gloss for countertops |

How to Polish PU Stone: My Step-by-Step Process

Polishing PU stone requires care to avoid damaging the material. Based on my experience, here’s a detailed guide to doing it right:

1. Assess the Surface

Before starting, inspect the PU stone for scratches, dullness, or stains. Determine whether it’s coated or uncoated and whether the goal is to restore shine or remove imperfections. I always start by cleaning the surface with a mild detergent and water to remove dirt, as debris can cause scratches during polishing.

2. Gather the Right Tools

Unlike natural stone, PU stone doesn’t require industrial polishers. Here’s what I use:

Soft polishing pads (foam or microfiber, 3000-8000 grit for finishing).

Polishing compound designed for plastics or synthetics (e.g., Novus #2 or Meguiar’s PlastX).

Orbital polisher or hand polishing for small areas.

Microfiber cloths for cleaning and buffing.

Water spray bottle to keep the surface damp (optional for wet polishing).

My Tip: Avoid coarse sandpaper (below 2000 grit) or aggressive compounds meant for natural stone, as they can gouge PU stone.

3. Test a Small Area

I can’t stress this enough: always test on a hidden section first. I once polished a PU stone tabletop without testing and ended up with swirl marks that were impossible to remove. Apply a small amount of polishing compound, work it in with a soft pad, and check the result.

4. Polish the Surface

For Minor Scratches or Dullness: Apply a small amount of polishing compound to a microfiber cloth or foam pad. Work in small, circular motions by hand or with an orbital polisher on low speed (1000-1500 RPM). Keep the surface slightly damp to reduce friction.

For Deeper Scratches: Start with a 3000-grit polishing pad to smooth the surface, then move to a finer 5000-8000 grit pad for shine. Follow with a polishing compound to enhance gloss.

For Coated Surfaces: Use a non-abrasive polish and a soft cloth to restore shine without removing the coating.

My Tip: Work in small sections (e.g., 12×12 inches) to ensure even results, and wipe away excess compound with a clean microfiber cloth.

5. Clean and Seal

After polishing, clean the surface with water and a mild detergent to remove residue. If the PU stone is uncoated or the coating was damaged, apply a polyurethane sealant or wax-based polish to protect the surface and maintain shine. I’ve used a spray-on sealant from Rust-Oleum for PU stone panels with great results.

6. Maintain the Finish

To keep the polished surface looking good:

Clean regularly with a damp cloth and mild soap.

Avoid abrasive cleaners or scrubbers.

Reapply sealant every 6-12 months for outdoor or high-traffic surfaces.

Challenges and Risks of Polishing PU Stone

Polishing PU stone isn’t without its pitfalls. Here are some challenges I’ve faced and how to avoid them:

1. Over-Polishing

Applying too much pressure or using overly abrasive tools can strip the surface or create uneven patches. I once over-polished a PU stone countertop, leaving it shinier in some areas than others, which looked patchy.

Solution: Use light pressure and high-grit pads, and check progress frequently.

2. Damage to Texture

If the PU stone has a textured finish, polishing can smooth it out, ruining the natural stone effect. A client once asked me to polish a textured PU stone wall, and the result was a slick surface that looked more like plastic than stone.

Solution: For textured surfaces, focus on cleaning rather than polishing, or use a matte polish to maintain the texture.

3. Coating Removal

Polishing a coated PU stone too aggressively can strip the protective layer, making it vulnerable to stains or UV damage. I’ve seen this happen with outdoor PU stone panels exposed to rain after polishing.

Solution: Use a non-abrasive polish and test for coating compatibility.

Alternatives to Polishing

If polishing seems too risky or unsuitable for your PU stone, consider these alternatives:

Cleaning: For minor dullness, a thorough cleaning with a mild detergent and water can restore the surface.

Repainting or Recoating: If the surface is heavily scratched or faded, apply a new Begins a new line of code.

PU stone-specific paint or sealant to refresh the look. – **Replacement**: If the damage is severe, replacing the panel may be more cost-effective than extensive polishing.

My Experience: Lessons from Polishing PU Stone

My first attempt at polishing PU stone was for a client’s decorative wall in a restaurant. The matte finish had dulled over time, and they wanted a subtle sheen. I used a fine polishing compound and a soft pad, testing a small corner first. The result was a smooth, satin-like finish that enhanced the stone-like appearance without looking overly glossy. However, I learned to avoid heavy polishing on textured PU stone after a later project went wrong, smoothing out the rugged charm of a faux granite panel.

Polishing PU stone is doable, but it’s not a one-size-fits-all process. Understanding the material, choosing the right tools, and proceeding cautiously are key to success. With the tips above, you can decide whether polishing is right for your PU stone and achieve a professional finish. If you’re unsure or have a specific question, drop it in the comments—I’m happy to share more insights from my projects!

Frequently Asked Questions

Q1: Can all PU stone surfaces be polished to a high gloss?

A: Not all PU stone can achieve a high gloss. Glossy or coated PU stone can be polished to a shine, but textured or matte finishes may lose their natural look. Check the manufacturer’s specs first.

Q2: What tools are best for polishing PU stone?

A: Use soft polishing pads (3000-8000 grit), a plastic-safe polishing compound (e.g., Novus #2), and a low-speed orbital polisher or microfiber cloths. Avoid coarse abrasives meant for natural stone.

Q3: Will polishing PU stone damage its protective coating?

A: Aggressive polishing can strip coatings, exposing the material to damage. Use non-abrasive compounds and test a small area to ensure the coating remains intact.

Q4: How do I maintain a polished PU stone surface?

A: Clean with mild soap and water, avoid abrasive scrubbers, and reapply a polyurethane sealant or wax every 6-12 months for protection, especially for outdoor surfaces.